WELCOME TO Uni Print

Uni print is the perfect choice for your business

Narrow web printing

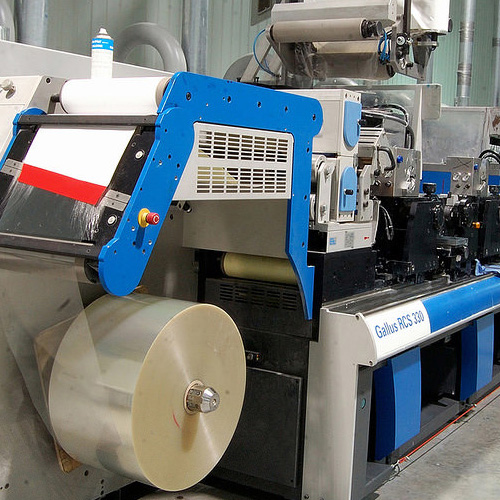

The heart of Uniprint narrow web printing is the Gallus RCS. Machines of this caliber are used to create, among other things, exclusive labels for products that are positioned at a high level in the market. Flexibility and proficiency of Gallus printing machines allow to perform the works of any complexity level in short terms. Gallus RCS is the latest word in label production technology: the fully servo-driven platform construction and a high automation degree assure the cost-effective production of medium-run products with absolute quality. The possibility of quick adjustments and changeovers, extremely easy maintenance and high technological flexibility provide high productivity of the Gallus RCS system. Switching of printing methods is performed without web interruption, the upper platform of the machines allows to place delamination and lamination devices, additional corona displacement, numbering heads, etc.

Prepress

The main prepress equipment is ESKO CDI Spark 2530 optic 15, a device for direct laser exposure of photopolymer plates, which enables us to get a high quality screen and halftone printing with the effect of 1%, which almost corresponds to the color rendering level of offset printing, but excludes its disadvantages. Dupont equipment ensures stability of photopolymer processing and fixation.

Production of rotary stencil cylinders ensures mobility in production.

We produce engraved brass cylinders for hot foil stamping on German equipment Impala that allows you to emboss the finest printed elements.

We also produce magnesia plates for hot stamping by etching.

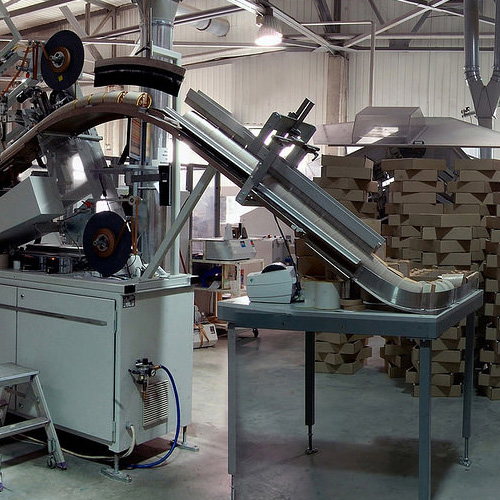

Postpress and raw material preparation

Inspection and cutting of s / k labels is made by 3 slitters, there is a machine for offline rotary die-cutting labels, machines for flat foil stamping and offline die-cutting, equipment for gluing, inspection and cutting sleeve, Large format slitters 1.6m used for cutting foil, films and paper to the required size with minimum waste which allows to work with mother jumbo. Equipment for the production of self-adhesive material allows you to produce in a short time self-adhesive materials, including special papers and films, and solve various technological problems.

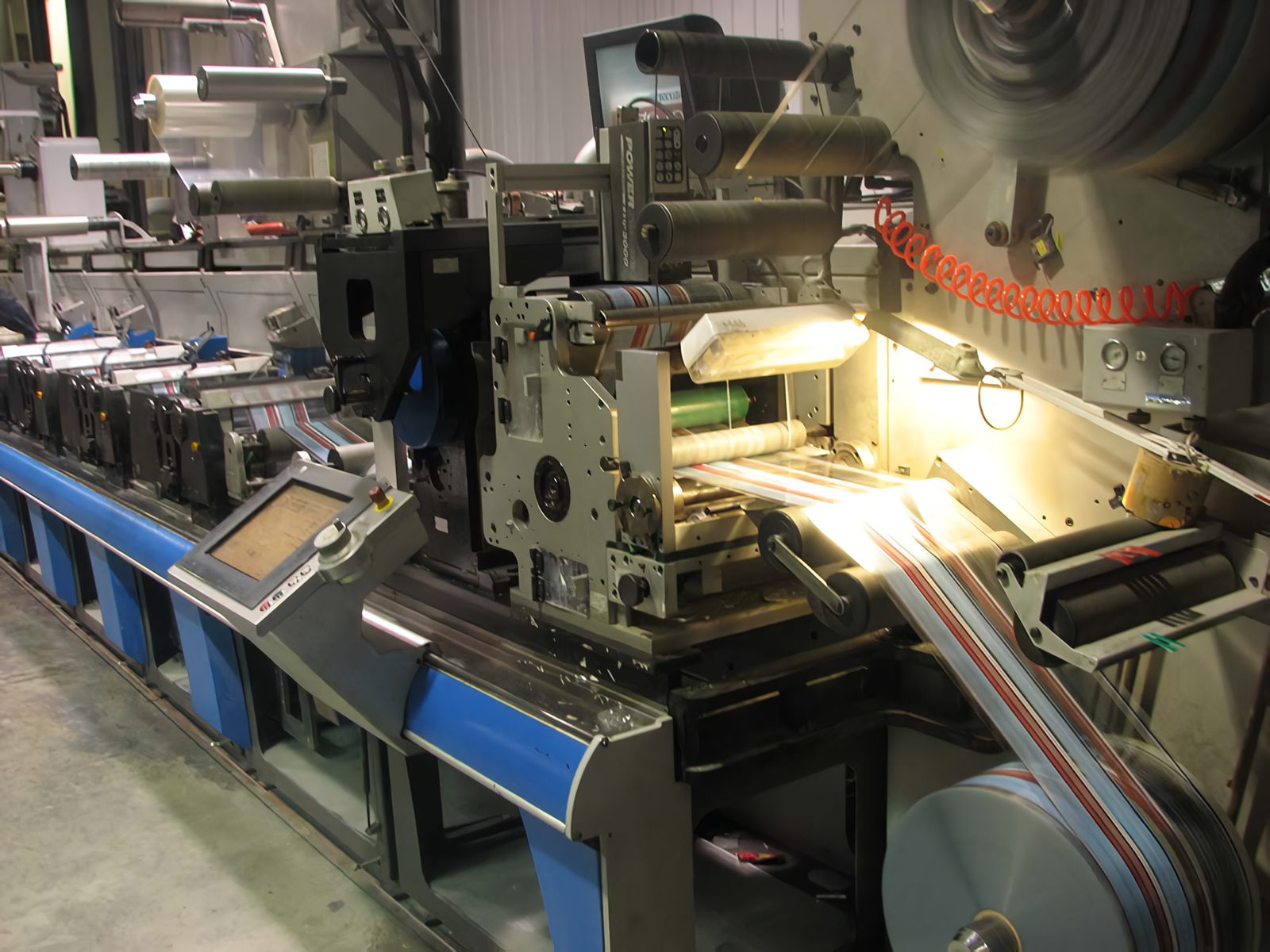

Rotogravure printing

Two 8-color machines, 1,000mm and 650mm, allow the processing of films, aluminum foil and paper. A web rotation unit enables coatings and images to be printed on the reverse side of the material.

Injection lamination

The machine is equipped with two PE slit extruders which enable processing of both sides of the material or laminating of additional material. The combination of materials can be paper, cardboard, films and aluminum foil

Responsibility

We are serious people

Creativity

We are passionnate

Quality

We are determined